The optimal choice of trimmer characteristics will not be enough for comfortable cutting of vegetation in the garden. Both for and for it is necessary to choose the right cutting tool. As such, a trimmer line (cord) or a special knife is used.

The type of vegetation is fundamental when choosing what to mow. For the convenience of work, the user can choose the type of cord, the type of trimmer head, the method of threading the cord into it, choose a knife of a certain shape. Therefore, you should familiarize yourself with these characteristics in more detail.

TRIMMER LINE (CORD)

The classic cutting tool for all types of tools is a special trimmer line or line, also sometimes called a string. Its thickness (diameter) ranges from 1.2 to 4 mm. For each trimmer, the maximum cord thickness is indicated, which can be used without overheating the engine and accelerated wear of the bushings.

In addition to differences in thickness, the trimmer cord also has a different cross-sectional shape: a circle, a polygon (from three to hexagon), an asterisk, rounded protrusions, etc. In addition, it can be twisted along the longitudinal axis in the form of a twisted square or a spiral-shaped round string, and have various notches and recesses. All of these tricks are designed to increase efficiency when mowing vegetation.

The most versatile is the round cross-section trimmer line, which can be used to cut both fresh grass and dead wood. In addition to this versatile cord, manufacturers also produce more specialized line.

Taking into account that the smaller the contact area of the cord with the stem, the greater the force of its impact, a figured cord with a cross-section in the form of a polygon or an asterisk with sharp corners has appeared. Later, for strength, particles of aluminum began to be added to it.

Square fishing line with a thickness of 2.4 mm and more will allow you to easily cope with thickets of dry weeds and even stems of raspberry bushes. The sprocket, on the other hand, is designed for gentle mowing of fresh grass. Due to the profile, it cuts vegetation cleaner, the grass leaves faster after cutting and does not dry out as often as after using a round fishing line.

Spiral-shaped round fishing line is considered low noise, but this parameter is only relevant for electric trimmers, since the sound of a running gasoline engine blocks the whistle from any fishing line.

When using a trimmer line with a figured section, its thickness should be taken less than the maximum for this trimmer - this will avoid problems with the supply of line from the mowing head. Fill such a cord into the spool with gloves.

Trimmer lines come in a variety of colors and in most cases this is not functional. But for some manufacturers, the color determines the diameter of the cord (for example, Stihl) or the properties of the material used (for example, Oregon).

For the manufacture of trimmer lines, nylon (polyamide) or polypropylene are used. Leading manufacturers use PP6 polypropylene for the manufacture of cords. Various low-quality polyethylene is often added to the fishing line of Chinese origin to reduce the cost. But in any case, after long-term storage, the polypropylene cord becomes brittle. To increase the elasticity, such a line should be soaked in water for half an hour before use.

Under no circumstances should thin wire or stranded wire be used as a trim cord. Thinking in this case about the strength and durability of the fishing line, they forget that the trimmer string is specially made in such a way as to break off to soften the dynamic impact on the transmission and the engine of the tool. In addition, the cable and wire still break off. At the same time, broken-off pieces dispersed to high speed easily pierce leather shoes.

TRIMMER HEAD

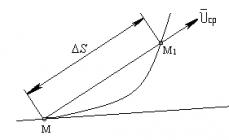

The trimmer head, often also called the mowing head, is a specially designed reel that contains a cord of a certain length. An 8-15 m piece of cord is wound onto the inner spool, the ends of which are pulled out of the reel to the required length as they wear out or break off when they encounter a too hard obstacle.

As a rule, for different models of trimmers, certain mowing heads are used, which differ in both the internal structure and the way of attachment. For some trimmer heads, special adapters are available that allow these heads to be used on trimmers of various models and manufacturers.

Trimmer heads are usually subdivided according to the type of line feeding into manual, semi-automatic and automatic. In the first, as the name implies, the line is fed from the head manually. To do this, you will have to stop working, turn off the trimmer and manually lengthen the ends of the cord.

For the second, it is enough to hit the ground with the mowing coil. In this case, by pressing a special button upon impact, the anchor mechanism is released and the cord is fed due to centrifugal force. Line lengthening is carried out with the trimmer working.

In the third option, to lengthen the cutting line, simply reduce the engine speed, then with a subsequent increase in speed, the trimmer line is automatically fed.

As follows from the above description, the most inconvenient is the mowing reel with manual cord feed, and the most optimal is the mowing head with automatic feed. However, she did not win much love from users due to the increased, in comparison with other types, line consumption. Therefore, the most popular and demanded today are semi-automatic trimmer heads.

Also, different models of trimmer heads differ in the way the line is threaded. They can be quick-charging (for example, Shindaiwa Speed-Feed), when there is no need to disassemble the reel to wind a new portion of the cord, and collapsible.

In the first version, you can leave the mowing reel on the trimmer. The end of the cord is threaded through both ears in the reel, then the required amount of line is wound and cut off. Or both ends of a pre-cut piece of cord of the required length are tucked into the corresponding holes and screwed on.

In the second option, to charge a new portion of the cord, the trimmer coil will need to be removed, disassembled and wound on the spool inside. Different models of reels have different ways of disassembling and winding the line. But in all cases, the line must be wound in the direction indicated by the arrow on the body (both ends in one direction).

On cheap Chinese mowing heads, the so-called "no-name", such an arrow is often absent. Also, branded models may have two arrows in different directions (when it is possible to use them on trimmers with different directions of head rotation). In this case, the cord must be wound in the direction of rotation of the shaft (that is, the engine must wind it). If the cord is wound in the wrong direction, then when the button hits the ground, it will fly out too much.

The opposite option is also possible - when the line does not feed when the semi-automatic mowing head hits the ground. This can be caused both by improper winding of the line, or by the fact that after installation on the trimmer, you simply forgot to pull the ends of the cord out of the retaining grooves on the spool.

Another nuisance when mowing vegetation with a trimmer line is the sintering of the turns inside the coil. This is due to the fact that, when meeting with an obstacle that is too hard, the cord is sharply decelerated. With such jerks, it is pulled inward and sticks to the part wound on the spool. As a result, it is necessary to interrupt work, disassemble the coil and tear the stuck together turns of the cord. In some cases, this can be avoided by spraying the line wound on a spool with silicone spray before installing it into the spool.

Most often, a semi-automatic head is used for trimmers, consisting of two spring-loaded parts (body and spool). Structurally, the spool can be in two versions. Two-section, where each end of the cord is wound into its own section, which reduces tangling and sintering. Or one-piece, when both ends of the line are wound together.

Our craftsmen came up with a simple, cheap and elegant way to turn a one-section spool into a two-section one, the essence of which can be understood from the above photos.

To do this, a ring is cut out of a strong and thin plastic plate, the inner diameter of which corresponds to the thickness of the spool in the winding zone of the fishing line, and the outer diameter to the diameter to the protrusions. That is, such a ring should move freely along the spool. Then a cut is made for the cord, the ring is cut, put on the spool and the cut is glued with tape. Now each end of the line can be wound into the section intended for it.

The prewound mowing head has two or four opposed holes from which the mowing ends protrude. In addition to feed spools, there are also trimmer heads with plug-in fixed lengths (such as the Oregon Jet-FIT).

In this case, the number of working "whiskers" can be up to twelve. Some users consider such a design to be quite convenient, but another part is unhappy, because they believe that this increases the consumption of the cord and it is necessary to stop working to replace it. In such heads, as a rule, a fishing line with transverse notches is used.

TRIMMER KNIFE

When mowing tall grass with the trimmer line, it will wrap around the spindle where the mowing head is attached. How often this will happen depends largely on the design of the head and the properties of the mowed grass, but it is practically impossible to completely avoid this. The optimal solution would be to cut not with a cord, but with a trimmer knife specially designed for such cases.

The trimmer knife used as a cutting tool can be made of plastic or metal and have a different number of blades (teeth) of various shapes.

On curved bar trimmer models, only plastic blades should be used (for the safety of the mower and commensurate with the flexibility of the flex shaft). In addition, they often come bundled with.

This can be either a special mowing head with replaceable removable plastic knives, or a one-piece design in the form of a circular knife with a different number of blades. Tough vegetation (dry grass, burdocks, nettles, etc.) is in the teeth of such trimmer knives.

For processing large areas and mowing not only grass, but also cutting shrubs or even young trees, metal knives are used. The only thing such trimmer knives are "afraid" is collisions with objects that are too hard for them (for example, stones).

Metal knives can only be used on straight bar trimmers. They cannot be mounted on tools with a curved shaft. This is due primarily to safety precautions. If, while mowing vegetation, the disc hits a solid obstacle, then in this case it is thrown back. With straight bar trimmers, the distance to the user's feet is much further.

Plus, the T (U) or J-shaped handle helps to hold the tool, and a special protruding limit bar is added to the D (O) -shaped handle, which rests on the leg does not allow the cutting tool to reach it. Curved bar trimmers are usually equipped with a D (O) -shaped handle without stopper.

Second, the high torque metal disc coulter puts a lot of stress on the flex shaft and motor, resulting in quick tool breakage.

As the experience of users shows, the shape of the blades (triangular, rectangular, etc.) has practically no effect on the quality and speed of mowing. But their quantity becomes important when using a hay trimmer. Three or four blade knives chop the grass too much when mowing.

The most optimal for haymaking are considered to be almost round eight-tooth knives or with four large and additional smaller teeth between them. Perforated discs with a large number of teeth are also popular - this lightweight trimmer cutter can be installed on low-power tools.

Using a trimmer cutter, that is, a circular knife with a large number of teeth, you can not only easily clean the area of luxurious perennial weeds, raspberries, etc., but also cut trees with a trunk diameter of several centimeters.

Trimmer heads are used for cutting grass and lawns. Such a device has a fairly simple device and is easy to operate. Thanks to this, the unit has become popular with the population and utilities. Low weight is an additional plus, almost any person can cope with the work of such a device. Consider the features of the unit and manufacturer reviews.

Description

Trimmer heads include a cutting element, a special bar, a propeller and a control mechanism with a handle. The unit is intended for cutting grass in the courtyard and garden areas. The compactness of the device and ease of control allow you to do high-quality work in the most inaccessible places. With this unit, you can also prune shrubs and young gardens. Adjustable elements allow you to set the desired cutting height of grass on lawns and sites.

When choosing trim heads, pay attention to the following parameters:

- Power indicator.

- The mass of the device.

- Type of food.

- Engine placement, which can be either top or bottom.

- A type of cutting part.

- Rod type.

Classification by type of line feed

Husqvarna trimmer heads are classified according to line feed method, namely:

- Manual type. The line is fed in this version by a mechanical method. To lengthen the cord, you will need to stop the operation of the device and pull out the edges of the cutting part by hand.

- Semiautomatic device... Such specimens allow changing the cord without touching the head of the ground surface. This option is implemented using a special key and an anchor mechanism, which makes it possible to lengthen the working part of the line due to centrifugal action. It is important that the whole procedure is carried out with the unit turned on.

- Automatic trimmer heads differ in that, during their operation, the lengthening of the cord is performed automatically after reducing the engine speed. The line is fed in the normal mode.

Of the above mechanisms, the manual version is not very practical and convenient. Automatic variations are also not popular due to the high line consumption. The optimal version will be semi-automatic execution.

Criterias of choice

When purchasing Champion trimmer heads and other models, you need to focus on the purpose of use of the unit. For a large area with a flat lawn surface, it is better to use light and not very powerful modifications. If it is supposed to process an overgrown summer cottage, it is more reasonable to take a model with a high power indicator.

The selection of the cutting element also plays an important role in the final functionality of the unit. The working part is a special fishing line or working knives. This takes into account the rigidity and density of the plants. The universal trimmer head will allow you to process most of the vegetation, but it is not always durable and efficient.

Device

The device in question is a special configuration reel, which is equipped with an internal cord. It can be of various sizes, it is screwed onto the inner element of the spool up to 15 meters long.

The edges of the line are set at a certain distance to allow work to be carried out. If it hits solid objects (stones, trees, etc.), the working element is destroyed. Depending on the type of fixture, the heads can have different configurations. The universal analog is suitable for most modifications. This is due to the possibility of using a number of special adapters.

Line threading

According to this parameter, trimmer heads can be divided into two categories:

- Fast charging. On such models, when winding the cord, it is not necessary to disassemble the spool. One edge of the next tucked line is wound into a reel and wound several times. After choosing the required length, the material is cut.

- Collapsible heads. To refuel them, you need to remove the coil from the unit, then remove the used line and wind a new analogue.

The working head contains special pointers in the form of arrows. They are responsible for the direction of movement of the working part during rotation. If it is necessary to wind the fishing line in the direction of rotation of the shaft, it is turned into a certain position. Excessive amount of cord is fraught with equipment failure.

If it is impossible to wind the cord after hitting the semi-automatic head, winding should be done again. Most likely, the user did not pull the ends of the scaffold out of the nests.

Popular models

Consider briefly the representatives of the most famous bobbin manufacturers on the domestic market:

- Trimmer head Oleo Mac М-10 / 11.25. This model belongs to professional semi-automatic options, is used when operating a brushcutter. The diameter of the working part is 13 centimeters, it is characterized by fast line threading.

- "Huskvarna T-45X"- has an open eyelet, easy line feed. Work items can be changed individually. Increased reliability and reduced wear are provided by a ball bearing surface.

- "Huskvarna T-35"... This model is an automatic line feed head (just lightly hit the reel on the ground). There is a tap and go function.

- Champion... Modification ET 1002KA belongs to the middle price category. Differs in ease of disassembly, strong vibration is not felt during operation.

- Trimmer head DDE. The variant of the Win 6 type is designed for mowing grass with a line with a diameter of 2-3 mm. Suitable for electric and petrol mowers with 10 mm working shaft. The maximum permissible speed on the shaft is 10 thousand rotations per minute.

- Autocut С-4-2. This head is suitable for brushcutters "Calm", is used for mowing grass and cleaning the territory. There is an automatic adjustment of the length of the working strings when the head touches the ground. Compatible with 2mm line.

Exploitation

When the cord meets solid objects, it stops abruptly, as a result of which the scaffold gets inside the device. It lies under the spool and sticks together. To rectify the situation, you will need to stop work and re-lay the line. As a prevention of such inconveniences, it is recommended to treat the forest with silicone grease before installing it into the reel.

In the device of the Autocut trimmer head, as in other semi-automatic models, two parts of the main element are distinguished: the body and the spool. Spring mechanisms are provided in both parts. The spool can be run in several configurations:

- Modifications with one section. In this case, both ends of the line are wound together.

- Models with a pair of compartments. In them, each edge is wound on a specific element. This design is more efficient, avoids wood tangling and sintering.

It is quite feasible to redesign a single section spool to a dual chamber version. This will require a strong plate, from which a circle with a diameter identical to the thickness of the spool is cut. This part is in free movement. Then a cut is made on the ring, mounted on the head and fixed with tape or glue.

Peculiarities

The universal trimmer head can be equipped with from two to four holes. They are opposite each other. Mowing ends are derived from these elements. In addition to these types of bobbins, there is a head designed for a certain size of the scaffold. In such coils, the number of whiskers increases to a dozen. Among users, opinions were divided about such devices.

Some consider such a unit to be more efficient. Others are confident that the line consumption will be significantly higher with a dubious improvement in the quality of work. In addition, the process will need to be interrupted to replace the scaffold. Consider the terrain and vegetation characteristics when choosing a trimmer. After that, you can choose the option that suits the best in a given situation.

The trimmer reel cuts the grass, but it will wear out and often need to be replaced. Recently, motorcycle or electric scythes have become widespread. The main working element of such a garden tool are spools with a fishing line tucked inside. Therefore, it is extremely important to choose a quality item so as not to waste your finances, because the device is quite expensive. To reduce the cost of servicing brushcutters, you can learn how to self-thread the forest into the trimmer reel.

Often, manufacturers of power tools do not complete their products with a number of devices that are necessary or useful for operation, offering to purchase them separately (as an additional option). With a brushcutter reel, the situation is different: since it is the main working element of a garden tool, all trimmers are supplied with it, but the quality of the reel from the scythe kit leaves much to be desired.

The consumer has to purchase the reel separately - this is done to increase sales and generate additional profit for manufacturers.

Below are questions about what a trimmer is, what coils are, and how to insert and fix the fishing line yourself.

What is a trimmer

A trimmer is understood as a brush or electric trimmer. In fact, it is a type of lawn mower (hand mower) that is designed for mowing grass. This is a modern braid. Originally designed for agricultural work, the main application of the trimmers was precisely lawn mowing.

For the first time the idea to create a trimmer came to mind of the American entrepreneur J. Bollas. While driving his car through an automatic car wash, he noticed that the principle of rotating brushes could be used to mow crops.

After that, he assembled a primitive trimmer from a tin can (as a spool) and a line threaded through the holes drilled in it. He installed the resulting structure on a pole, on which the engine from a moped was previously mounted. The device mowed not only wheat, but also grass. Realizing that he would earn a lot of money on the sale of the scythe, the entrepreneur improved his product and gave it the name “Weed killer”. A feature of the invention was the ability to mow the grass around the trees - the forest cut the grass perfectly, but did not injure the bark.

The main purpose of such a tool was to mow grass in small areas in places where classic wheeled vehicles cannot be used:

- in the presence of a large number of shrubs;

- in gardens with lots of trees;

- near fences and fences;

- if the site has uneven relief.

All trimmers include a barbell - the main structural element. A gasoline or electric engine is attached to the rod from one end, and a reel with a fishing line is put on the other - the main working element. In this case, the type of transmission can be any - it is limited only by the capabilities of the manufacturer and commercial parameters.

Why this tool is called differently

Trimmer was originally understood as a hand-held lawnmower with an electric motor. At the same time, the mower was powered both from the mains and from the battery, which can be installed on a rod or carried in a special pouch.

The main cutting element is the fishing line, which creates some restrictions on the type of processed grass: you can only mow plants with a thin and soft stem. The mowing area is limited by the length of the cable or the capacity of the battery. However, recently, braids with gasoline engines have also been called trimmers. They give greater mobility to the worker, which can significantly increase the size of the site.

But electric and gasoline scythes were originally varieties of lawn mowers, however, with the advent of the trimmer, these designs have ceased to be in demand and are now rarely produced, and their names have passed to trimmers - most people are more accustomed to call this tool that way.

Coil specifics

In the modern world (both in the city and in the countryside) it is practically impossible to do without such a modern and useful tool as a trimmer. It is widely used by employees of municipal services in large cities, such devices are also in demand in farms, they are used to improve summer cottages, vegetable gardens, orchards, etc.

Photo of the complete set of the coil of the garden trimmer.However, it should be remembered that the main working element is the trimmer head - a spool with line. It is this element that most often fails and requires maintenance. The price of the reels has a wide range (from $ 10 to $ 150), which makes such a tool even more expensive. Any manufacturer (even a branded one) usually equips its product with an inexpensive and low-quality coil. However, it is possible to work for a rather long time with a primitive coil, subject to timely maintenance of it.

Like any other mechanical element, the coil requires cleaning of accumulated grass, cooling in case of overheating and filling with lubricant. However, coils often fail for various reasons, and buying new ones or carrying broken ones for repair is quite expensive. In this case, almost all malfunctions can be eliminated independently. It is not difficult to disassemble the coil, especially if you use the instructions.

The first part that often fails on the trimmer reel is the line. The line is a consumable for which the manufacturer is not responsible. At the same time, on many models of reels, changing the fishing line is a difficult procedure (and for some brands it is impossible). Attempting to replace the line with a material other than the original line may destroy the reel.

The reel itself (the part of the element on which the fishing line is wound) rarely fails, while the grooves through which the working part of the fishing line is threaded and which holds it can collapse (grind off), since they are almost always made of plastic.

Video about cable lubrication, shank replacement, installation of the guard and trimmer coil:

Despite the abundance of spare parts for trimmers on sale, not everyone can afford to buy them, in addition, there are often restrictions on available products. For example, manufacturers make "individual" mounts for the trimmer, the universal reel will not fit on such a mount. This often makes it impossible to obtain a suitable coil for the price. Some manufacturers make spools designed for thin line (up to 3 mm in diameter), which significantly limits the trimmer's capabilities. Therefore, there is an option to make the coil yourself.

How to make a coil yourself

The basis of a homemade reel is a disc made of durable material. It is best to use textolite about 5 mm thick for these purposes. It is strong and reliable enough. The size of the disc depends on the size of the trimmer and personal experience - how it is more convenient to work.

Next, a hole should be drilled in the center of the disc. The diameter of the hole must be equal to the diameter of the rod axis (the latter is attached to the rotating shaft of the motor). In this case, it is extremely important to determine exactly the center of the disc. After that, 4 holes should be drilled for the line. Their diameter will be equal to the diameter of the fishing line, and they will be located in pairs on opposite sides of the axis (2 on one side, 2 on the other from the axis of rotation). In this case, the design of the reel is greatly simplified: it is not required to wind a large amount of fishing line, but it is enough to fix (tie) a small section of it through the finished holes.

To give the structure the necessary strength and reliability, it is recommended to find a spring, the inner diameter of which will be equal to the diameter of the shaft, and install it on the shaft over the finished disc.

Once the line is tucked in and secured to the disc, you can start testing. The fishing line does not need to be fixed to the disc motionless: even when threaded through the holes, it will not fall out, because the engine gives high revolutions to the shaft, and the centrifugal force is sufficient to hold the fishing line under load.

This design, instead of a purchased trimmer coil, has many advantages: you can install any line (both thin and thick) into it, the device itself is practically "indestructible", and it will not take very long to purchase a new coil.

The disadvantages of this homemade product include the following:

- the need to cut a pair of pieces of fishing line of the same length;

- when installing without attaching the fishing line, it is necessary to make sure that equal lengths of fishing line hang from the reel.

Video about winding the line on the trimmer reel:

The body can be used from an old coil - it rarely breaks.

Conclusion

Such a self-made coil can significantly reduce the cost of operating the trimmer, which improves its operating parameters. You can use the same trimmer to cut small shrubs as well as soft and thin lawn grass.

In the modern agaric economy, a lot of all kinds of tools have been divorced, which are created in order to make life easier for summer residents and amateur gardeners. In my opinion, a grass trimmer lawnmower is one of the very simple and ingenious inventions that can turn your weedy garden plot into a well-groomed lawn in a matter of minutes. But no matter how thoughtful the invention is, it needs care and repair. I am not a supporter of reworking industrial tools, but in order to save money, I came up with and describe a useful addition to the line trimmer.

Line trimmer, DIY repair:

When you start a power tool on the farm, you should immediately understand that in addition to the electrical part, there is also a mechanical one, which requires timely maintenance, cleaning, cooling and lubrication. Electric fishing trimmer is no exception. I'll tell you a little about my trimmer, I do not specify the model and parameters - this is not so important. The first thing that was covered in it was a button, when I disassembled it, there were clear signs of melting, I think this was caused by power surges in the network and the processes occurring at the time of switching. To put it simply, it was of poor quality. Like many other trimmer parts, the button can be replaced with another one that matches the parameters (current and design). The trimmer line, well, like other attachments, is a consumable item, and it is only natural that I ran out of it too. As a typical kulibin, I began to poke in everything that came to hand, from an ordinary thick fishing line to a thicker and more durable special trimmer line. Despite my natural curiosity and curiosity, I acted within the framework of the instructions read, but even this did not save my coil from destruction.

Coil from my trimmer

Coil from my trimmer  Coil side view

Coil side view As if the coil (meaning the part itself where the fishing line is wound) did not really suffer in the process of my experiments, but the special grooves holding the fishing line simply grinded off, it is not surprising because they are plastic, and I have been using the trimmer for a long time and quite often. Of course, even for old trimmer models, spare parts are sold, ranging from line to engines. But the new reel seemed a bit expensive to me, the price just “bite”, and I was not satisfied with the fact that it was impossible to fill a line with a thickness of 5 mm (my trimmer is designed for using a line with a thickness of 2 mm).

And so ... after much thought on how to modify the trimmer coil, I came up with an idea that was simple to implement and quite easy to use. It is necessary to cut a circle out of strong material, I used 4mm thick foil textolite.

PCB disc with holes

PCB disc with holes You need to make a hole in the center of the disc that is suitable in diameter to the axis of the rotating shaft, and four more holes (or more) suitable in diameter for your line.

Disc and pieces of used line

Disc and pieces of used line The idea is very simple, you do not use a reel, do not wind the line, but simply tie it to the holes and attach the disc to the holder according to the same principle as the previous reel, it is only important to find a suitable spring for fastening reliability (whoever has a trimmer will immediately understand about what spring we are talking about).

Tying pieces of line to the disc

Tying pieces of line to the disc  Refuel the line and attach the disc to the holder

Refuel the line and attach the disc to the holder The fishing line can not be tied, in spite of the high revs, for something, and so it holds quite firmly and does not fly out. With the proposed organization of the direction of the line in the trimmer, you win in the fact that you can hook there line of any diameter and configuration, while you will never need to spend money on new reels. But there are also disadvantages, you will need to cut pieces of line of a certain length, this may not always be convenient. But in terms of time and laboriousness, refueling the line is neither slightly nor worse than in the classical way into your own reel.

This is what my version looks like

This is what my version looks like I took a photo without a trimmer and a retaining spring, since it was not at the cottage at that moment. But I boldly declare that the result of my revision has surpassed all my expectations. Now I have significantly reduced the cost of consumables for the trimmer, which once again proves the triumph of reason over the dogmas of instructions attached to purchased tools.

To look after the lawn near the house or summer cottage, you cannot do without a trimmer. As you know, the coils of these tools wear out quickly. However, in this case, a lot depends on the vegetation that a person is struggling with. If we talk about one-year-old grass, then the coil wear is extremely low. However, weeds are very difficult to control.

How to choose a model?

The market is mainly represented by plastic modifications. They are produced with steel cores. First of all, you should pay attention to the diameter of the line. For one-year-old grass and small weeds, a size of 1.5 mm is suitable. The coil height must not exceed 80 mm. The wrapping system is most often used of a semi-automatic type. However, there are models that only fire when you touch the ground. Thus, the line wears out much more slowly. There is such a modification in the region of 800 rubles.

Reviews of the coil Bosch K101

The specified coil for trimmer universal reviews from buyers mostly receives positive. First of all, it should be noted the low weight of the model. The width of the presented modification is 72 mm. The manufacturer provides a wrapping system of a semi-automatic type.

The line for the head is selected with a diameter of 1.3 mm. The model copes with one-year-old grass remarkably. As the owners note, the coil wear is extremely low. With large weeds, owners may have certain problems. Most often, it is the cup that breaks. The presented coil costs around 650 rubles.

Overview of the Bosch K103 model

This trimmer reel (universal, metal) is in high demand. She weighs only 0.3 kg. Suitable for Hyundai and Makita brand instruments. Among the features of the modification, a strong fishing line should be noted. The manufacturer provides a wrapping system of an automatic type. The core itself is made of metal and rarely breaks.

The head height in this case is 67 mm. The cap is flat and is not worn out frequently. With annual grass, problems are rare. However, some users wear out the cover. The protective cover in this case is made of plastic. This coil is sold on the market at a price of 900 rubles.

Opinion about Bosch K105

The specified trimmer reel (universal) is produced with a semi-automatic wrapping system. In this case, the mount is screw type. The head height of the model is 6 mm. The fishing line is provided by the manufacturer with a small diameter. According to the buyers, it is very easy to unwind. There is a protective cap at the top of the structure. This reel weighs exactly 0.32 kg. The open eyelet allows the line to swing freely. Suitable for trimmer heads from various manufacturers. The user is able to buy a coil at a price of 1200 rubles.

Features of EFCO 8100 trimmer spools

This universal trimmer coil (photo shown below) is sold with a special adapter for connection. In this case, the wrapping system is of an automatic type. The diameter of the mount is 6.2 mm. The head height of the model is 76 mm. The line is used directly with a diameter of 1.3 mm.

The device is fastened using a screw method. The protective cover at the coil is made of shock-resistant plastic. The manufacturer does not provide a cup for the presented model. According to customer reviews, the coil is connected without problems. The model handles small grass very quickly. However, large weeds should be avoided. The user is able to buy the presented coil for 1300 rubles.

Reviews of Trimmer Reel EFCO 8155

The presented trimmer reel (universal) is produced with a plastic cover. The model copes with one-year-old grass successfully. The same goes for small weeds. The diameter of the mount at the head is 6.2 mm. The line itself is made with a diameter of 1.3 mm. This head is suitable for many garden trimmers. According to the buyers, the line unwinds very quickly. The wrapping system is of a semi-automatic type.

The cup in this case is made of high-impact plastic of the VS series. The head landing diameter is as much as 1.7 mm. There is a special adapter for connecting the head. According to customers, it wears out slowly. In stores, this coil is sold at a price of 900 rubles.

EFCO 3060 trimmer reel overview

This is a very compact and inexpensive trimmer reel (universal). The wrapping system is of a semi-automatic type. The mount is installed with a diameter of 6.2 mm. The line itself wears out very slowly. According to the buyers, the model is capable of mowing grass of any height. The adapter is installed with a threaded connection. The cup in this case reliably protects the head body. The presented reel is suitable for trimmers "Intertul", "Hyundai" and other manufacturers. You can buy a model for 850 rubles.

Flymo 15 trimmer reels review

This trimmer reel (universal) is manufactured with an automatic wrapping system. The cup is small in thickness. Buyers complain that it wears out very quickly. However, it is important to consider the low price of the product. The height of the installed head is 74 mm. Directly the fishing line is used with a small diameter. The core in this case is made entirely of metal. Suitable for garden trimmers from various manufacturers. You can find the specified coil on the market for 700 rubles.

Features of Flymo 22 trimmer spools

This electric trimmer reel (universal) is manufactured with a reliable winding mechanism. The diameter of the mount in this case is 6.5 mm. The installed head height is 72 mm. Suitable for Hyundai and Makita trimmers. According to the buyers, the head unwinds very quickly. The model copes with one-year-old grass without problems.

According to the owners, the coil casing is of high quality. In this case, the cup practically does not wear out. However, when working, it is important to beware of large weeds. The user is able to purchase this model for 1200 rubles.